The post Micromeretics and powder rheology: Particle size and distribution and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>FUNDAMENTAL PROPERTIES OF PARTICLES

The following are the five fundamental properties of powders from which other properties can be derived:

- Particle size and size distribution

- Particle volume

- Particle number

- Particle shape

- Particle surface area

Particle Size and Size Distribution-

Spherical or symmetrical particle: The size of a spherical particle can be expressed in terms of its diameter. The surface area is proportional to the square of the diameter, and the volume is proportional to the cube of the diameter. Thus, for a perfect sphere, the surface area is given by

S = πd2 (1)

And the volume is given by

V = πd3 / 6 (2)

As the volume of a sphere is πd3/6, the diameter of a spherical particle with a volume V is given by

d = 3√ 6V / π (3)

Nonspherical or asymmetrical particle: In naturally occurring particulate solids and milled solids, the shape of particles is irregular with different numbers of faces. An asymmetric particle has a definite surface area and volume, but its length varies with its orientation. As the degree of asymmetry increases, so does the difficulty of expressing size in terms of meaningful diameter. Hence, an asymmetric or a nonspherical particle is often considered to be approximate to a sphere that can then be characterized by determining its diameter. Because measurement is then based on a hypothetical sphere, which represents only an approximation to the true shape of the particle, the dimension is referred to as the equivalent spherical diameter of the particle. The size of the particle is expressed in terms of equivalent spherical diameters by using some measurable properties such as surface area, volume, diameter or density. Thus,

- Surface diameter, ds, is the diameter of a sphere having the same surface area as that of the asymmetric particle in question.

- Volume diameter, dv, is the diameter of a sphere having the same volume as the asymmetric particle in question.

- Projected diameter, dp, is the diameter of a sphere having the same observed area as the asymmetric particle in question when viewed normal to its most stable plain. This diameter is usually determined by the microscopic technique.

- Stokes’ diameter, dst, is the diameter of a sphere with the same density as the asymmetric particle in question and which undergoes sedimentation as the same rate as the asymmetric particle in a given fluid within the range of Stokes’ law. This diameter is usually measured by the sedimentation method.

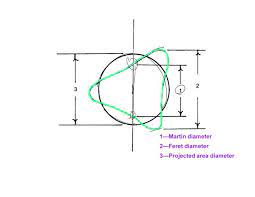

The other two diameters, the values of which are dependent on both the orientation and the shape of the particles, are Feret’s diameter and Martin’s diameter.

- Feret’s diameter is the mean distance between two tangents on the opposite sides of the particle parallel to some fixed direction.

- Martin’s diameter is the length of the line that bisects the particle. The line may be drawn in any direction but must be in the same direction for all the particles measured.

Fig 1 – Equivalent diameters of asymmetric particle (taken from micromeretics.pdf page 1)

Particle size distribution: A particle population that consists of spheres or equivalent spheres with uniform dimensions is monosized and its characteristics can be described by a single diameter or an equivalent diameter. However, most pharmaceutical powders are polydisperse (i.e. consists of a mixture of particles of varying sizes and shapes). Therefore, it is necessary to know not only the size of particle in the sample but also the number of particles of each size present in the sample. This is called the particle size distribution.

Table 1 – Particle size distribution data obtained by particle size analysis

| Particle size range (µm) | Mean particle diameter d (µm) | Frequency n (no. of particles in each

diameter) |

Frequency (%) | nd |

| 10–30 | 20 | 100 | 4.5 | 2000 |

| 30–50 | 40 | 200 | 9.1 | 8000 |

| 50–70 | 60 | 400 | 18.2 | 24,000 |

| 70–90 | 80 | 800 | 36.4 | 64,000 |

| 90–110 | 100 | 400 | 18.2 | 40,000 |

| 110–130 | 120 | 200 | 9.1 | 24,000 |

| 130–150 | 140 | 100 | 4.5 | 14,000 |

| Ɛn = 2200 | Ɛnd = 17,600 |

Multiple choice questions (MCQs)

1.One micrometer is equal to

a)10-6 cm

b)10-3 cm

c)10-6 m

d)10-3 m

2.Which of the following properties of a particle significantly affects the physical, chemical and biological properties of the drug?

a)Density

b)Sedimentation

c)Size

d)Surface area

3.It is difficult to express the size of particle in a meaningful diameter

a)Irregular in shape

b)Irregular surface

c)Spherical shape

d)Uniform in size

4.The type of particle diameter obtained largely depends on

a)Method by which it is determined

b)Nature of the powder

c)Procedure by which it is calculated

d)Way it is defined and described

5.When cumulative percent frequency on a probability scale is plotted against logarithm of the particle size, 50 percent on the probability scale gives the powder particle diameter of

a)Arithmetic mean

b)Arithmetic mode

c)Geometric mean

d)Harmonic mean

6.Which one of these distributions is more important in the design of dosage forms?

a)Gaussian

b)Normal

c)Number

d)Weight

7.In the formulation development of emulsion and suspensions, what type of diameter is important?

a)Length number

b)Projected

c)Sieve

d)Stokes

8.Sieving method is used for size distribution analysis of powder. The disadvantage of this method is:

a)Agglomerates can be identified

b)Attrition of powder is possible

c)Large number of sieves are required

d)Tedious and time consuming

9.While using sedimentation method for size analysis, addition of a deflocculating agent to a suspension is necessary in order to

a)Accelerate the process of sedimentation

b)Make the particles spherical

c)Prevent the aggregation

d)Satisfy Reynolds number

10.Stoke’s law cannot be used, if Reynolds number is more than

a).2

b)1.8

c)9.0

d)18.0

11.Andreasen apparatus consist of

a)Balance

b)Electrodes

c)Hydrometer

d)Pipette

12.When coulter-counter apparatus is employed for powder analysis, the following criteria is important

a)Dispersion medium should be colored

b)Dispersion medium should be conducting

c)Suspended particles should be charged

d)Suspended particles should be suspended

13.In coulter-counter, as the particles move through the orifice, the event that occurs is

a)Conductance between the electrodes increases

b)Electronic scanners produce photographs for volume measurement

c)Resistance between the electrodes increases

d)Sedimentation increases

14.Fisher subsieve sizer is used to determine the surface area of the powder. The surface area is measured based on the change in

a)Light transmission of gas that reaches the detector

b)Pressure across the compacted powder

c)Thermal conductivity of gas across the powdered pack

d)Weight of powder when air is passed through the powdered pack

15.High repose angle of the granules indicated

a)Bulk density of the granules

b)Porosity of the granules

c)Roughness of the granule surface

d)Smoothness of the granule surface

Solutions:

- c) 10-6 m

- d) Surface area

- a) Irregular in shape

- a) Method by which it is determined

- c) Geometric mean

- d) Weight

- d) Stokes

- b) Attrition of powder is possible

- c) Prevent the aggregation

- a) 0.2

- c) Hydrometer

- b) Dispersion medium should be conducting

- c) Resistance between the electrodes increases

- d) Weight of powder when air is passed through the powdered pack

- c) Roughness of the granule surface

References:

1. GAURAV KUMAR JAIN – THEORY & PRACTICE OF PHYSICAL PHARMACY, 1st edition 2012 Elsevier, page no. 24-27.

2. Martins Physical Pharmacy, 6th edition 2011, page no. 800-802.

List of Successful GPATINDIAN CANDIDATES

Participate in Online FREE GPAT TEST: CLICK HERE

Participate in Online FREE Pharmacist TEST: CLICK HERE

Participate in Online FREE Drug Inspector TEST: CLICK HERE

Participate in CSIR NET JRF Mock Test

The post Micromeretics and powder rheology: Particle size and distribution and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>The post Micromeretics and Powder Rheology: Methods of determining particle size and volume – Optical microscopy, Sieving and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>Equivalent diameter: It is used to determine projected area diameter, Feret’s diameter and Martin’s diameter.

Range of analysis: 1 μm to about 100 μm.

Methodology:

- Firstly, the powdered substance is placed over the stage and obseved through the lens.

- The microscope eyepiece is fitted with a micrometer by which the size of the particles can be estimated.

- The field can be projected onto a screen where the particles are measured more easily, or a photograph can be taken from which a slide is prepared and projected on a screen for measurement.

- The particles are measured along an arbitrarily chosen fixed line, generally made horizontally across the center of the particle.

- Popular measurements are; Feret diameter — Martin diameter — Projected area diameter.

- These measurements can be stored as screenshot for long term use.

Table 1 – Representation of number distribution values obtained by the microscopic method

| Ocular

divisions |

Particle size

range (µm) |

Mean particle

size (µm) |

Frequency (no. of

particles in each diameter) |

Frequency

(%) |

Cumulative

frequency (%) |

Log

particle size |

| 0–1 | 0–20 | 10 | As counted | – | – | 1.00 |

| 1–2 | 20–40 | 30 | As counted | – | – | 1.47 |

Advantage:

- Agglomerates can be detected.

Disadvantages:

- This method is tedious and slow as at least 300–500 particles must be counted to obtain a good size distribution analysis.

- The measured diameter of the particles represents two dimensions only (i.e. the length and the breadth) and an estimate of the depth is not obtained.

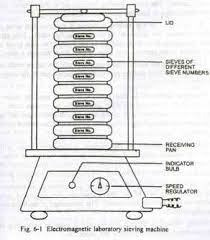

Sieving Technique:

Equivalent diameter: Sieve diameter—the particle dimension that passes through a square aperture.

Range of analysis: 5 μm to about 1000 μm.

Methodology:

- Mass of sample is placed on the proper sieve in a mechanical shaker.

- The powder is shaken for a definite period of time, and the material that passes through one sieve and is retained on the next finer sieve is collected and weighed.

- When a detailed analysis is desired, the sieves can be arranged in a nest of about five with the coarsest at the top.

Machines:

- Shaking

- Vibration

- Use a jet of air to clear the sieves

- Ultra-sonics (wet sieving)

Fig 1 – Arrangements of sieves during sieving and sizes of standard sieves (taken from size separation slideshare.net)

Table 2 – Sieve no. with aperture size

| US sieve no. | Aperture size |

| 10 | 2.00mm |

| 14 | 1.40mm |

| 18 | 1.00mm |

| 20 | 840 µm |

| 25 | 710 µm |

| 40 | 420 µm |

| 60 | 258 µm |

| 80 | 180 µm |

| 100 | 149 µm |

| 120 | 125 µm |

| 200 | 74 µm |

| 400 | 37 µm |

Table 3 – Representation of weight distribution values obtained by the sieving method

| Sieve numbers

(passed/retained) |

Size range

(µm) |

Mean size

(µm) |

Weight retained

(g) |

Weight

retained (%) |

Cumulative weight

retained (%) |

Log particle

size |

| 25/40 | 710–420 | 565 | As weighed | – | – | 2.75 |

| 40/60 | 420–258 | 339 | As weighed | – | – | 2.53 |

Advantages:

- This method is inexpensive, simple and rapid, with little variation between operators.

- Micromesh sieves are available for extending the lower limit to 10 μm.

Disadvantages:

- Appreciable amount of sample (normally at least 25 g) is needed.

- Measurement of particle below size of 50 μm is difficult.

- Sieving of cohesive powders is difficult as they tend to clog the sieve openings.

- It gives two-dimensional estimate of size because passage through the sieve aperture is frequently more dependent on maximum width and thickness than on length.

- Aggregation of particles may occur during sieving because of the generation of electrostatic charge and thus, the actual particle size may not be obtained.

- Attrition of particles during sieving may lead to size reduction.

Multiple choice question (MCQs)

1.Andreason apparatus consist of

a)Reference electrode

b)Pipette

c)Glass electrode

d)Hydrogen electrode

2.For a sphere value of αs / αv equals to

a)6

b)9

c)8

d)18

3.The physical, chemical, and pharmacological properties of a drug are directly affected by

a)Size

b)Surface area

c)Both of the above

d)None of the above

4.____ is the science and technology of small particles

a)Micromeretics

b)Microscopy

c)Rheology

d)None of the above

5.The unit of particle size used is in

a)Kilometer(km)

b)Centimeter(cm)

c)Millimeter(mm)

d)Micrometer(µm)

6.1 micrometer(µm) is equal to

a)10-5m

b)10-6m

c)10-7m

d)10-8m

7.Particle size with diameter of 0.5 to 1.0 micrometers(µm) is useful for

a)Emulsions

b)Suspensions

c)Both of the above

d)None of the above

8.The size of a sphere is freely stated in terms of its

a)Area

b)Diameter

c)Radius

d)Volume

9.Which property affect physical, chemical and biological property of drug?

a)Density

b)Surface area

c)Particle size

d)All of the above

10.Particle size can be reduced by,

a)Mortar and pestle

b)Sieve

c)Grinder

d)Both a and c

11.Sedimentation rate can be decreased by …………. Particle size,

a)Increase

b)Decrease

c)Unchanged

d)None of the above

12.Which is smallest?

a)Micrometer

b)Millimeter

c)Nanometer

d)Catharometer

13.Micromeretics is a study of

a)Particle size

b)Particle shape

c)Particle distribution

d)All of the above

14.Particle size is determined by

a)Sieving method

b)Sedimentation method

c)Microscopy

d)All of the above

15.Sedimentation of suspension is determined by

a)Stokes law

b)Car’s index

c)Hausner ratio

d)None of the above

Solutions:

- b) pipette

- a) 6

- c) Both of the above

- a) Micromeretics

- d)Micrometer(µm)

- b) 10-6m

- c) Both of the above

- b) Diameter

- d) All of the above

- d) Both a and c

- b) Decrease

- c) Nanometer

- d) All of the above

- d) All of the above

- a) Stokes law

References:

1. GAURAV KUMAR JAIN – THEORY & PRACTICE OF PHYSICAL PHARMACY, 1st edition 2012 Elsevier, page no. 31-34.

2. Martins Physical Pharmacy, 6th edition 2011, page no. 817-819.

List of Successful GPATINDIAN CANDIDATES

Participate in Online FREE GPAT TEST: CLICK HERE

Participate in Online FREE Pharmacist TEST: CLICK HERE

Participate in Online FREE Drug Inspector TEST: CLICK HERE

Participate in CSIR NET JRF Mock Test

The post Micromeretics and Powder Rheology: Methods of determining particle size and volume – Optical microscopy, Sieving and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>The post Micromeretics and powder rheology: Determining surface areas – Permeability method and Adsorption method and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>SURFACE AREA DETERMINATION METHODS:

The surface area can be determined directly by one of the following two methods:

- Adsorption method

- Air permeability method

Adsorption Method – Particles with a small particle size (large specific surface) are good adsorbents for the adsorption of gases and of solutes from the solution. The amount of gas or solute adsorbed on the sample of powder to form a monolayer calculated, and from this data, the surface area of the powder is determined.

Solute adsorption method

Principle: Adsorption of a solute from its solution onto the surface of the adsorbent powder whose area is to be determined Here, solute refers to substance of known surface area, which gets adsorbed and forms a monolayer such as stearic acid and adsorbent powder refers to powder sample whose surface area is to be determined. It adsorbs the solute molecules.

- A solution of a known amount of solute (5.0 g) is first prepared in a medium in which the adsorbent powder is insoluble.

- A known amount of the adsorbent powder (0.5 g) is then added to the solution and the contents are stirred till equilibrium has been attained.

- The powder is then filtered and the amount of solute remaining in the solution (4.0 g) is determined by a suitable method.

- The difference between the quantity of solute added and that remaining in the solution gives the quantity of solute that has been adsorbed (1.0 g).

- From this value, the amount of solute adsorbed per gram of the powder is calculated.

Since the surface area of one molecule of solute is known, the specific surface area of the powder is calculated by the following equation:

Specific surface area of the power = number of molecules adsorbed × surface area of one molecule of solute

Gas adsorption method

Surface area determination by gas adsorption method is carried out using an instrument called quantasorb.

Method: The powders whose surface area is to be determined are introduced into a cell in the instrument and nitrogen (adsorbate gas) and helium (inert, nonadsorbing gas) are passed through the powder in the cell. A thermal conductivity detector measures the amount of nitrogen adsorbed at every equilibrium pressure and a bell-shaped curve is obtained on a strip-chart recorder. The signal height gives the rate of adsorption of nitrogen gas, and the area under the curve provides the amount of gas adsorbed on the powder sample. The volume of nitrogen gas Vm in cubic centimetre adsorbed by 1 g of the powder when the monolayer is given by the BET equation:

P / V(Ƿ0-Ƿ) = 1 / Vmb + (b-1)Ƿ / Vmb Ƿ0

where V is the volume of gas in cm3 adsorbed per gram of powder at pressure Ƿ.

Ƿ0 is the saturated vapour pressure of liquefied nitrogen at the temperature of the experiment.

b is a constant and it gives the difference between the heat of adsorption and the heat of liquefaction of the nitrogen gas.

A plot of Ƿ /V(Ƿ0– Ƿ) versus p/po generally gives a straight line. The slope and intercept yield the values b and Vm, respectively.

The specific surface of the powder is obtained by applying the following equation:

Sw = AmN X Vm / (m/p)

where m/p is the molar volume of the gas, which is equal to 22,414 cm3/mol at NTP. N is Avogadro’s number 6.02 × 1023. Am is the area of a single close packed gas molecule absorbed as a monolayer on the surface of the powder particles. For nitrogen, the value is 16.2 × 10 -16 cm2.

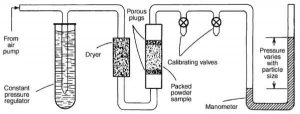

Air Permeability Method:

Principle: This method is based on the principle that the resistance offered to the flow of a fluid, such as air, through a plug of compacted powder is proportional to the surface area of the powder. The greater the surface area per gram of the powder, the greater is the resistance to flow. Surface area determination by the air permeability method is generally carried out with an instrument called the Fisher subsieve sizer.

Fig 1 – Representation of Fisher subsieve sizer apparatus (taken from Fisher subsieve sizer powder metallurgy)

Method:

- Powder is packed in sample holder.

- Packing appears as series of capillaries.

- Air is allowed to pass through the capillaries at constant pressure.

- Resistance is created as air passes through capillaries thus causing pressure drop.

- Greater the surface area greater the resistance.

- Air permeability is inversely proportional to the surface area.

According to Poiseuille’s equation:

V = πd4∆pt / 128lƞ

where V is the volume of air flowing through a capillary of internal diameter d and length l in t seconds under a pressure difference of ‘P. The viscosity of the fluid (air) is K poise.

When the air is allowed to pass through the plug of a compacted powder, resistance to the flow of air occurs. This resistance is related to the surface area of the powder. According to the Kozeny–Carman equation derived from Poiseuille’s equation:

V = A/ƞSw2 X ∆p/kl X E3/ (1-E)2

where A is the cross-sectional area of the plug, K is a constant (usually 5.0 ± 0.5) and E is the porosity.

Multiple choice questions (MCQs)

1.___ is not the fundamental property of powders

a)Particle shape

b)Particle volume

c)Particle number

d)Bulk density

2.____ is not the derived property of powders

a)Particle shape

b)Tapped density

c)Bulk density

d)Carr’s index

3.Equivalent spherical diameter of asymmetric particle can be calculated using

a)Surface area

b)Volume

c)Diameter

d)All of the above

4.Surface area of spherical particle is given by

a)Πd

b)Πd2

c)Πd3

d)Πd4

___ diameter is the diameter of sphere having the same surface area as that of the asymmetric particle in question

a)Surface

b)Projected

c)Volume

d)None of these

6.___ diameter is the diameter of sphere having the same surface area as that of the asymmetric particle in question when viewed in its most stable plane

a)Surface

b)Projected

c)Volume

d)None of these

7.___ diameter is the diameter of sphere having the same density as that of the asymmetric particle in question and which undergoes sedimentation at the same rate as the asymmetric particle

a)Surface

b)Projected

c)Volume

d)Stokes

8.When the ____ of particle is plotted against the mean particle size, the curve obtained is called as number frequency distribution curves

a)Number

b)Volume

c)Area

d)Thickness

9.When the ____ of particle is plotted against the mean particle size, the curve obtained is called as weight distribution frequency curve

a)Number

b)Weight

c)Area

d)Thickness

10.Bell shape curve obtained by plotting frequency verses logarithm of particle diameter is referred as log normal distribution curve

a)Number distribution frequency curve

b)Weight distribution frequency curve

c)Log normal distribution curve

d)None of these

11.When the log particle size is plotted against the cumulative percent frequency on a probability scale showing linear relationship is called as

a)Log probability plot

b)Weight distribution frequency

c)Log normal distribution curve

d)None of the above

12.___ can be characterized by two parameters that is the slope of the line and a reference point

a)Log probability plot

b)Weight distribution frequency

c)Log normal distribution curve

d)None of the above

13.____ is the logarithm of particle size equivalent to 50% on the probability scale (that is the 50% size)

a)Reference point

b)Standard point

c)Freezing point

d)Boiling point

14.___ is defined as the number of particles per unit weight of a powder

a)Particle weight

b)Particle frequency

c)Particle number

d)All of the above

15.____ is not the method of determination of particle size

a)Microscopic method

b)Sieving

c)Sedimentation

d)Melting

Solutions:

- d) Bulk density

- a)Particle shape

- d)All of the above

- b)Πd2

- a)Surface

- c)Volume

- d)Stokes

- a)Number

- b)Weight

- c)Log normal distribution curve

- a)Log probability plot

- a)Log probability plot

- a)Reference point

- c)Particle number

- d)Melting

References:

1. GAURAV KUMAR JAIN – THEORY & PRACTICE OF PHYSICAL PHARMACY, 1st edition 2012 Elsevier, page no. 44-47.

2. Martins Physical Pharmacy, 6th edition 2011, page no. 825-828.

List of Successful GPATINDIAN CANDIDATES

Participate in Online FREE GPAT TEST: CLICK HERE

Participate in Online FREE Pharmacist TEST: CLICK HERE

Participate in Online FREE Drug Inspector TEST: CLICK HERE

Participate in CSIR NET JRF Mock Test

The post Micromeretics and powder rheology: Determining surface areas – Permeability method and Adsorption method and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>The post Micromeretics and powder rheology: Derived properties of Powders – Packing arrangement, Porosity and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector Exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>- Packing geometry

- Porosity

- Density

- Bulkiness

- Flow property

Packing Geometry: A set of particles can be filled into a volume of space to produce a powder bed, which is in static equilibrium owing to the interaction of gravitational and adhesive/cohesive forces. By slight vibration of the bed, particles can be mobilized, and at static equilibrium, they occupy a different spatial volume than before. The change in bulk volume has been produced by rearranging the packing geometry of the particles. In general, such geometric rearrangements result in a transition from loosely packed particles to more tightly packed ones. A set of uniform-sized spherical particles can be arranged in many different geometric configurations; however, the two extreme packing arrangements are as follows:

Cubic arrangement—particles are most loosely packed and have a porosity of 48%.

Rhombohedral arrangement—particles are most densely packed and have a porosity of only 26%.

- It is to be expected that the particles of ordinary powders may have any porosity intermediate between the two extreme packing arrangements, 26–48%.

- Porosities below the theoretical minimum of 26% are possible in a powder bed with wide size range particles wherein the void spaces between coarse particles may become filled with finer particles.

- Porosities above the theoretical maximum of 48% are possible, if the particles are irregularly shaped and highly textured. Such particles arch or bridge within the powder bed through interlocking.

- Tightly packed particles require a higher driving force to produce powder flow than loosely packed particles of the same powder due to increase in cohesion between the particles.

- The porosity used to characterize packing geometry is linked to the bulk density of the powder.

Porosity (E): Porosity is a measure of the air spaces or voids in a material. In a powder bed, three types of air spaces or voids can be distinguished.

- Open intraparticulate voids: Those within a single particle but open to the external environment.

- Closed intraparticulate voids: Those within a single particle but closed to the external environment.

- Interparticulate voids: The air spaces between individual particles.

Based on the types of voids, three interpretations of powder volume are proposed as shown below:

| Volume | Dełnition | Formula | Interpretation |

| Bulk(Vb) | Total volume occupied by the entire powder mass

(including voids) |

Vb= M/Ƿb | Vb= Total volume |

| Granular(Vg) | Volume of the solid particles excluding interparticulate (but not intraparticulate) void | Vg= M/Ƿg | Vg=Vb-interparticulate space |

| True(Vt) | Volume of the solid particles excluding both inter-

and intraparticulate voids |

Vt= M/Ƿt | Vt= Vb– (inter- and intraparticu-

late space) |

Note: M is the mass and Ub, Ug and Ut are bulk, granular and true density, respectively.

Table 1 – Three interpretations of powder volume based on the types of voids

The ratio of the total volume of void spaces (Vv) to the bulk volume of the material is often selected to monitor the progress of compression. This ratio Vv/Vb is referred to as the porosity of the material:

Vv = Vb – Vt

Therefore porosity is:

E = Vb – Vt / Vb = 1- Vt / Vb

Porosity is frequently expressed as a percentage:

E = 100 [1- Vt / Vb]

Multiple choice questions (MCQs)

1.___ equation can be used to convert number distribution to weight distributions with minimum calculation

a)Hatch Choate

b)Einstein

c)Faraday

d)Newton

2.Optical microscopy is used for determination of particle size in the range of

a)0.2 – 100µm

b)0.02-10µm

c)0.002-100µm

d)0.0002-100µm

3.____ is used for the determination of particle size distribution

a)Oven

b)Melting point apparatus

c)Potentiometer

d)Andreason apparatus

4.____ of the powder is defined as the surface area per unit volume or per unit weight

a)Angle of repose

b)Bulk density

c)True density

d)Specific surface

5.____ is not the method of adsorption for determination of surface area

a)By using a solute which forms monolayer

b)By using adsorption of gas on powder

c)Microscopy

d)Air permeability method

6.For a non porous material, bulk volume is equal to

a)Thickness

b)True volume

c)Diameter

d)Friability

7.For a porous material _____ is not equal to true volume

a)Thickness

b)Density

c)Bulk volume

d)Number

8.____ is defined as the ratio of mass of a powder and its true volume

a)True volume

b)Density

c)Bulk volume

d)Weight

9.Porous materials have internal pores or capillary spaces which are known as

a)True volume

b)Density

c)Bulk volume

d)Voids

10.____ is not the type of packing of particles

a)Closest

b)Loosest

c)Rhombohedral

d)Triangular

11.The fraction of total volume occupied by the free space between the particles is called as

a)Volume

b)Porosity

c)Tortuosity

d)Density

12.____ is not the type of density

a)True

b)Bulk

c)Granule

d)Volume

13.______ density is the density of the actual solid material devoid of free spaces

a)True

b)Bulk

c)Granule

d)Liquid

14.____ density is defined as the ratio of the given mass of a powder and its bulk volume

a)True

b)Bulk

c)Granule

d)Liquid

15.____ density is defined as the ratio of the given mass of a powder and its true volume

a)True

b)Bulk

c)Granule

d)Liquid

Solutions:

- a)Hatch Choate

- a) 2 – 100µm

- d) Andreason apparatus

- d) Specific surface

- c) Microscopy

- b) True volume

- c) Bulk volume

- b)Density

- d) Voids

- c) Rhombohedral

- b) Porosity

- d) Volume

- a) True

- b) Bulk

- a) True

References:

1. GAURAV KUMAR JAIN – THEORY & PRACTICE OF PHYSICAL PHARMACY, 1st edition 2012 Elsevier, page no. 48-50.

2. Martins Physical Pharmacy, 6th edition 2011, page no. 834-835.

List of Successful GPATINDIAN CANDIDATES

Participate in Online FREE GPAT TEST: CLICK HERE

Participate in Online FREE Pharmacist TEST: CLICK HERE

Participate in Online FREE Drug Inspector TEST: CLICK HERE

Participate in CSIR NET JRF Mock Test

The post Micromeretics and powder rheology: Derived properties of Powders – Packing arrangement, Porosity and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector Exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>The post Micromeretics and powder rheology: Derived properties of powders – Densities, bulkiness and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>Table 1 – Types of densities

| Density | Dełnition | Formula | Determination | Comment |

| Bulk(Ƿb) | Mass divided by bulk volume | Ƿb = M/Vb | Bulk density apparatus, pycnometer | It is characteristic of the powder.

Dependent on particle packing as the powder consolidates |

| Granular(Ƿg) | Mass divided by granular

volume |

Ƿg = M/Vg | Mercury displacement | |

| True(Ƿt) | Mass divided by true volume | Ƿt = M/Vt | Helium densitometer | It is characteristic of the particle. |

| Tapped(Ƿt) | Mass divided by volume

obtained by compacting bulk volume by tapping |

Mechanical tapping device Jolting volumeter | Use to characterize powder Ńow |

DENSITY DETERMINATION METHODS:

Bulk Density: Bulk density is determined by measuring the volume of the known mass of powder that has been passed through a screen into a graduated cylinder (Method I) or through a volume measuring apparatus into a cup (Method II).

Method I—Graduated cylinder method

Approximately 50 g of powder sample (M), previously passed through sieve no. 18 to break up agglomerates that may have formed during storage, is introduced into a 100-mL graduated cylinder without compacting. The apparent volume (Vb) is then read to the nearest graduated unit. The bulk density is calculated in g/cm3 by the formula

M / Vb

Method II—Scott volumeter

A known volume of a powder is allowed to flow through the scott volumeter apparatus into the sample receiving cup and the weight of the powder is determined. The bulk density is calculated in g/cm3 as described above.

Tapped Density: Tapped density is determined by mechanically tapping a graduated cylinder containing a powder sample.

Method

Approximately 50 g of powder sample (M), previously passed through sieve no. 18, is introduced into a 100-mL graduated cylinder without compacting. After observing the apparent volume(Vb), the cylinder is mechanically tapped by raising the cylinder and allowing it to drop under its own weight using a mechanical tapped density tester that provides a fixed drop of 142 mm at a nominal rate of 300 drops per minute. The cylinder is tapped 500 times initially and the tapped volume is measured (Vx). The tapping is repeated an additional 750 times and the tapped volume (Vy) is measured. If the difference between the two volumes is less than 2%, Vy is the final tapped volume. If the difference between the two volumes is more than 2%, then an additional 1250 tappings in increments is recommended until the difference between successive measurements is less than 2%. The tapped density is calculated in g/cm3 by the following formula:

M / Vy

True Density:

Gas pycnometer

Gas pycnometer is a device used to measure the density, or more accurately the volume, of the powder. In a gas pycnometer, the volume occupied by a known mass of powder is determined by measuring the volume of gas displaced by the powder. A gas pycnometer is also sometimes referred to as a helium pycnometer. Helium is a nonadsorbing gas that penetrates the smallest pores and crevices and is useful in determining true density, particularly of porous solids.

The working equation for a gas pycnometer is

Vt = Vc (U1 – Us / U1 – U2)

Where, The reading on the scale at this stage denotes Us. The difference between U1 and Us gives the volume occupied by the powder sample.

Liquid displacement

The pycnometer can be used to determine the density of a solid object using liquid in which the solid does not dissolve. It uses a working liquid with well-known density, such as benzene, ethyl alcohol and water, for estimating true density of nonporous solid particles since these liquids cannot efficiently penetrate the smallest pores and crevices of a porous material.

The density of the measured solid object is calculated as

Ƿs = Ms / Vs

Where, Ms is mass of powder sample and Vs is volume of measured solid object.

Granular Density:

Mercury displacement method or mercury porosimetry

The volume of granules can be measured by the mercury displacement method. The method is similar to the liquid displacement method, but here instead of a working liquid, mercury is selected as a solvent. Mercury is suitable to determine granular density because it fills the interparticulate voids but fails to penetrate intraparticulate spaces due to its large size, which is of the order 10 μm.

Mercury porosimetry involves the intrusion of mercury, a nonwetting liquid, at high pressure into a material. The pore size can be determined based on the external pressure needed to force the liquid into a pore against the opposing force of the liquid’s surface tension.

Bulkiness:

The reciprocal of bulk density is often called bulk or bulkiness. It is an important consideration in the packaging of the solid powders. For example, the bulk densities of calcium carbonate vary from 0.1 to 1.3, and the lightest or bulkiest type would require a container about 13 times larger than that needed for the heaviest type. A decrease in particle size increases the bulkiness.

Multiple choice questions (MCQs)

1.If hausner ratio of granule is in the range of 1.26-1.34 indicates ____ type of flow

a)Excellent

b)Good

c)Fair

d)Passable

2._____ technique is utilized for estimation of surface diameter

a)Air permeability

b)Vacuum

c)Filtration

d)Weighing

3.The angle of repose values are utilized in

a)Tablet manufacturing

b)Opthalmic products

c)Biphasic liquids

d)None of the above

4.____ = 100 X (tapped density – bulk density) / tapped density

a)Porosity

b)Hausner ratio

c)Compressibility index

d)None of the above

5.Flow property of powders can be enhanced by

a)Altering particle size

b)Altering particle shape

c)Altering surface area

d)All of the above

6.Particle size can be reduced by

a)Mortar and pestle

b)Sieve

c)Grinder

d)Both a and c

7.Method for determining surface area

a)Absorption method

b)Adsorption method

c)Air permeability method

d)Both b and c

8.The specific surface is

a)Surface area per unit volume

b)Surface area per unit weight

c)Both a and b

d)None of these

9.Sieving errors can arise due to

a)Loading of sieves

b)Duration of sieving

c)Intensity of agitation

d)All of the above

10.A sphere has ____ surface area

a)Maximum

b)Minimum

c)Normal

d)None of the above

11.The adsorbed layer in adsorption method is monomolecular at

a)Low pressure

b)High pressure

c)Very low pressure

d)Very high pressure

12.In sieve shaker, the particles are separated on the basis of

a)Particle shape

b)Particle size

c)Particle volume

d)Particle density

13.Sieve number indicates the number of meshes in

a)2.54mm

b)25.4mm

c)254mm

d)0.254mm

14.As per IP 1996 fine powder should pass through sieve number

a)10

b)22

c)44

d)85

15.Diameter represented by the length of line that bisects particle image is known as

a)Martin diameter

b)Feret’s diameter

c)Projected diameter

d)Stokes diameter

Solutions:

- d) Passable

- a) Air permeability

- a) Tablet manufacturing

- c) Compressibility index

- d) All of the above

- d) Both a and c

- d) Both b and c

- c) Both a and b

- d) All of the above

- b) Minimum

- a) Low pressure

- b) Particle size

- b) 4mm

- d) 85

- a) Martin diameter

References:

1. GAURAV KUMAR JAIN – THEORY & PRACTICE OF PHYSICAL PHARMACY, 1st edition 2012 Elsevier, page no. 52-56.

2. Martins Physical Pharmacy, 6th edition 2011, page no. 835-842.

List of Successful GPATINDIAN CANDIDATES

Participate in Online FREE GPAT TEST: CLICK HERE

Participate in Online FREE Pharmacist TEST: CLICK HERE

Participate in Online FREE Drug Inspector TEST: CLICK HERE

Participate in CSIR NET JRF Mock Test

The post Micromeretics and powder rheology: Derived properties of powders – Densities, bulkiness and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam appeared first on Gpatindia: Pharmacy Jobs, Admissions, Scholarships, Conference,Grants, Exam Alerts.

]]>