Rotary Cutter Mill and Roller Mill Principle, Construction, Uses, Advantage, Disadvantage, Question Answer for GPAT, GATE, Pharmacist, Drug Inspector & NIPER JEE Exam

Rotary Cutter Mill

Principle

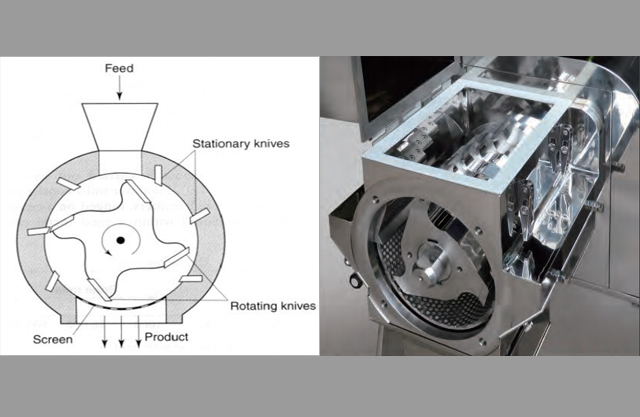

In Rotary cutter mill, feed material is size reduced by continuous cutting and shearing by the help of sharp knives

Construction

In this mill, the milling chamber contains 2 types of knives: stationary knives and rotating knives. A rotor disc is mounted horizontally which consist of 2 to 12 knives placed at equal distance. The casing contains several stationary knives and the hopper is placed above it. The screen which controls the size of the particle is present below the casing. A receiver is placed at the bottom of the mill where the product is collected.

Working

The rotor disc rotates at a speed of 200-900 rotations per minute. The feed is loaded and it comes down due to gravity. Due to the rotations made by the rotator disc, the feed material comes in close contact between the stationary and rotating knives which results in size reduction. Small particles pass through the screen while the coarser particles are held again by the rotating knives and the same procedure is repeated till the desired size is obtained. The shape and size of the particles depends on the size of rotor, gap between rotating and stationary knives and the opening of sieve.

Uses

- It results in particle size 80-100 mesh

- Used for tough and fibrous material

- Size reduction of drugs extracted from medicinal plants and animal tissues

- It is also used for the production of rubber, plastics and recycling of paper

Variants

Double runner disc mill- It consist of two vertical discs which rotates in opposite direction. Else all the parts are and working is similar to the cutter mill.

Roller Mill

Principle

This mill works on the principle of compression by applying stress. Stress is applied by rotating heavy wheels or rollers.

Construction

Roller mill consist of two cylindrical rollers made up of stone or metal where rollers have diameter ranging from few mm to a meter. Rollers rotate on their longitudinal axis where one of the rollers is subjected to motor while the other one run freely. The size of the particle depends on the gap between the rollers.

Working

The material is fed from the hopper into the gap between the rollers and rollers are also allowed to rotate at the same time. Size reduction occur when the feed pass through the rollers under high pressure. The product is then collected in the receiver at the bottom of the mill.

Uses

- Used for crushing and cracking of seeds before extraction of fixed oils.

- To crush soft tissues to help in penetration of solvent during extraction process

Multiple Choice Questions (MCQs)

1. Which mode of stress is applied in roller mill?

A. Impact

B. Attrition

C. Compression

D. Cutting

2. Which part of the cutter mill controls the size of particle?

A. Rotor disc

B. Screen

C. Receiver

D. Both B and C

3. What is the speed of rotor disc in cutter mill?

A. 1000 rotations per min

B. 2000 Rotations per min

C. 500 Rotations per min

D. None of the above

4. Which type of materials is size reduced by cutter mill?

A. Fibrous material

B. Abrasive material

C. Hard material

D. Soft material

5. Match the following-

A. Use of roller mill 1. Compression

B. Use of cutter mill 2. Cutting

C. Principle of roller mill 3. Used for cracking seeds

D. Principle of cutter mill 4. Used for tough and fibrous materials

6. How is the stress applied in roller mill?

A. Hammers

B. Rollers

C. Wheels

D. Both B and C

7. What is the only difference in the cutter mill and double runner disc mill?

A. Rotor disc performs more rotations per min in double runner disc mill

B. 2 screens are present in double runner disc mill

C. Two discs are present which rotates in opposite direction in double runner disc mill

D. No. of knives are more in double runner disc mill

8. Which of the following statement is NOT true?

A. Cutter mill consist of 14-20 knives placed at unequal distance

B. In roller mill, Size reduction occur when the feed pass through the rollers under high pressure

C. Cutter mill results in particle size 80-100 mesh

D. The rotor disc rotates at a speed of 200-900 rotations per minute

9. Particle size depends on which of the following factor in the cutter mill?

A. Size of rotor

B. Gap between rotating and stationary knives

C. Opening of sieve

D. All of the above

10. Which of the following mill is engaged in the manufacturing of rubber?

A. Hammer mill

B. Roller mill

C. Ball mill

D. None of the above

ANSWERS:

1. Compression

2. Screen

3. 500 rotations per min

4. Fibrous material

5. A – 3 B – 4 C – 1 D – 2

6. Both B and C

7. Two discs are present which rotates in opposite direction in double runner disc mill

8. Cutter mill consist of 14-20 knives placed at unequal distance

9. All of the above

10. None of the above

List of Successful GPATINDIAN CANDIDATES

Participate in Online FREE GPAT TEST: CLICK HERE

Participate in Online FREE Pharmacist TEST: CLICK HERE

Participate in Online FREE Drug Inspector TEST: CLICK HERE

Participate in CSIR NET JRF Mock Test