Micromeretics and Powder Rheology: Methods of determining particle size and volume – Optical microscopy, Sieving and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam

Optical Microscopy:

Equivalent diameter: It is used to determine projected area diameter, Feret’s diameter and Martin’s diameter.

Range of analysis: 1 μm to about 100 μm.

Methodology:

- Firstly, the powdered substance is placed over the stage and obseved through the lens.

- The microscope eyepiece is fitted with a micrometer by which the size of the particles can be estimated.

- The field can be projected onto a screen where the particles are measured more easily, or a photograph can be taken from which a slide is prepared and projected on a screen for measurement.

- The particles are measured along an arbitrarily chosen fixed line, generally made horizontally across the center of the particle.

- Popular measurements are; Feret diameter — Martin diameter — Projected area diameter.

- These measurements can be stored as screenshot for long term use.

Table 1 – Representation of number distribution values obtained by the microscopic method

| Ocular

divisions |

Particle size

range (µm) |

Mean particle

size (µm) |

Frequency (no. of

particles in each diameter) |

Frequency

(%) |

Cumulative

frequency (%) |

Log

particle size |

| 0–1 | 0–20 | 10 | As counted | – | – | 1.00 |

| 1–2 | 20–40 | 30 | As counted | – | – | 1.47 |

Advantage:

- Agglomerates can be detected.

Disadvantages:

- This method is tedious and slow as at least 300–500 particles must be counted to obtain a good size distribution analysis.

- The measured diameter of the particles represents two dimensions only (i.e. the length and the breadth) and an estimate of the depth is not obtained.

Sieving Technique:

Equivalent diameter: Sieve diameter—the particle dimension that passes through a square aperture.

Range of analysis: 5 μm to about 1000 μm.

Methodology:

- Mass of sample is placed on the proper sieve in a mechanical shaker.

- The powder is shaken for a definite period of time, and the material that passes through one sieve and is retained on the next finer sieve is collected and weighed.

- When a detailed analysis is desired, the sieves can be arranged in a nest of about five with the coarsest at the top.

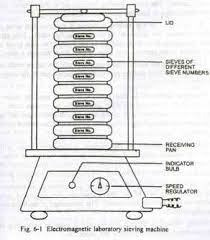

Machines:

- Shaking

- Vibration

- Use a jet of air to clear the sieves

- Ultra-sonics (wet sieving)

Fig 1 – Arrangements of sieves during sieving and sizes of standard sieves (taken from size separation slideshare.net)

Table 2 – Sieve no. with aperture size

| US sieve no. | Aperture size |

| 10 | 2.00mm |

| 14 | 1.40mm |

| 18 | 1.00mm |

| 20 | 840 µm |

| 25 | 710 µm |

| 40 | 420 µm |

| 60 | 258 µm |

| 80 | 180 µm |

| 100 | 149 µm |

| 120 | 125 µm |

| 200 | 74 µm |

| 400 | 37 µm |

Table 3 – Representation of weight distribution values obtained by the sieving method

| Sieve numbers

(passed/retained) |

Size range

(µm) |

Mean size

(µm) |

Weight retained

(g) |

Weight

retained (%) |

Cumulative weight

retained (%) |

Log particle

size |

| 25/40 | 710–420 | 565 | As weighed | – | – | 2.75 |

| 40/60 | 420–258 | 339 | As weighed | – | – | 2.53 |

Advantages:

- This method is inexpensive, simple and rapid, with little variation between operators.

- Micromesh sieves are available for extending the lower limit to 10 μm.

Disadvantages:

- Appreciable amount of sample (normally at least 25 g) is needed.

- Measurement of particle below size of 50 μm is difficult.

- Sieving of cohesive powders is difficult as they tend to clog the sieve openings.

- It gives two-dimensional estimate of size because passage through the sieve aperture is frequently more dependent on maximum width and thickness than on length.

- Aggregation of particles may occur during sieving because of the generation of electrostatic charge and thus, the actual particle size may not be obtained.

- Attrition of particles during sieving may lead to size reduction.

Multiple choice question (MCQs)

1.Andreason apparatus consist of

a)Reference electrode

b)Pipette

c)Glass electrode

d)Hydrogen electrode

2.For a sphere value of αs / αv equals to

a)6

b)9

c)8

d)18

3.The physical, chemical, and pharmacological properties of a drug are directly affected by

a)Size

b)Surface area

c)Both of the above

d)None of the above

4.____ is the science and technology of small particles

a)Micromeretics

b)Microscopy

c)Rheology

d)None of the above

5.The unit of particle size used is in

a)Kilometer(km)

b)Centimeter(cm)

c)Millimeter(mm)

d)Micrometer(µm)

6.1 micrometer(µm) is equal to

a)10-5m

b)10-6m

c)10-7m

d)10-8m

7.Particle size with diameter of 0.5 to 1.0 micrometers(µm) is useful for

a)Emulsions

b)Suspensions

c)Both of the above

d)None of the above

8.The size of a sphere is freely stated in terms of its

a)Area

b)Diameter

c)Radius

d)Volume

9.Which property affect physical, chemical and biological property of drug?

a)Density

b)Surface area

c)Particle size

d)All of the above

10.Particle size can be reduced by,

a)Mortar and pestle

b)Sieve

c)Grinder

d)Both a and c

11.Sedimentation rate can be decreased by …………. Particle size,

a)Increase

b)Decrease

c)Unchanged

d)None of the above

12.Which is smallest?

a)Micrometer

b)Millimeter

c)Nanometer

d)Catharometer

13.Micromeretics is a study of

a)Particle size

b)Particle shape

c)Particle distribution

d)All of the above

14.Particle size is determined by

a)Sieving method

b)Sedimentation method

c)Microscopy

d)All of the above

15.Sedimentation of suspension is determined by

a)Stokes law

b)Car’s index

c)Hausner ratio

d)None of the above

Solutions:

- b) pipette

- a) 6

- c) Both of the above

- a) Micromeretics

- d)Micrometer(µm)

- b) 10-6m

- c) Both of the above

- b) Diameter

- d) All of the above

- d) Both a and c

- b) Decrease

- c) Nanometer

- d) All of the above

- d) All of the above

- a) Stokes law

References:

1. GAURAV KUMAR JAIN – THEORY & PRACTICE OF PHYSICAL PHARMACY, 1st edition 2012 Elsevier, page no. 31-34.

2. Martins Physical Pharmacy, 6th edition 2011, page no. 817-819.

List of Successful GPATINDIAN CANDIDATES

Participate in Online FREE GPAT TEST: CLICK HERE

Participate in Online FREE Pharmacist TEST: CLICK HERE

Participate in Online FREE Drug Inspector TEST: CLICK HERE

Participate in CSIR NET JRF Mock Test