Pharmaceutical Aerosols: Manufacturing and packaging methods and MCQs for GPAT, NIPER, Pharmacist and Drug Inspector exam

Packaging methods: Two methods have been used to package aerosol products. Unlike non-aerosol products, part of the manufacturing of necessity takes place during the filling operation. The propellant and product concentrate must be brought together in a way that ensures uniformity of product. Depending on the nature of the product concentrate, the aerosol can be filled by a cold-filling or a pressure-filling process. There are advantages and disadvantages to both methods, and there are many factors that must be considered before deciding which process to use.

Manufacture of pharmaceutical aerosols:

- Pressure filling apparatus

- Cold filling apparatus

- Compressed gas filling apparatus

PRESSURE FILLING APPARATUS – It consists of a pressure burette capable of metering small volumes of liquefied gas into the aerosol container under pressure. Propellant is added through an inlet valve located at the bottom or top of the pressure burette. The propellant is allowed to flow with its own vapor pressure in the container through aerosol valve. The trapped air escapes out from the upper valve. The propellant stops flowing when the pressure of burette and container becomes equal. If further propellant is to be added, a hose (rubber pipe) leading to a cylinder of nitrogen is attached to the upper valve, the pressure exerted by nitrogen helps in the flow of the propellant into the container. Another pressure filling device makes use of piston arrangement and is capable of maintaining positive pressure . This type of device cannot be used for filling inhalation aerosols which have metered valves.

PROCEDURE:

- This method involves filling of the concentrate into the container at the room temperature.

- Then the valve is placed in the container and crimped.

- Through the opening of the valve the propellant are added or it can be added “under the cap”.

- Since the opening of the valve are smaller in size ranging from 0.018-0.030 inches, it limits the production and the process becomes slow.

- But with the use of rotary filling machines and newer filling heads where the propellants are filled through valve stem, the production rate is increased.

- The trapped air in the container and air present in head space is removed before filling the propellant to protect the products from getting adversely affected.

- Various units used in pressure filling line are arranged in the following order : Unscrambler , Air cleaner , Concentrate filler , Valve placer , Purger ,Valve crimper , Propellant filler ,Water bath , Labeler , Coder and Packing table .

- Purger ,vacuum crimper and pressure filler are replaced with a single unit if filling is carried by ‘under the cap’ method.

ADVANTAGES OF PRESSURE FILLING:

- Solutions, emulsions, suspensions can be filled by this method as chilling does not occur.

- Contamination due to moisture is less.

- High production speed can be achieved.

- Loss of propellant is less.

DISADVANTAGES OF PRESSURE FILLING:

- Certain types of metering valves can be handled only by the cold filling process or through use of an under the cap filler and valve crimper.

- Process is slower than Cold filling method.

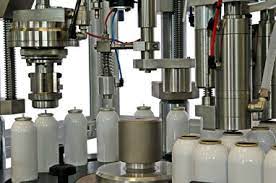

Figure 1 – Pressure filling equipment

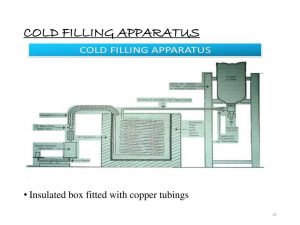

COLD FILLING APPARATUS – It consist of an insulated box fitted with copper tubings and the tubings are coiled to increase the area exposed to cooling. The insulated box should be filled with dry ice or acetone prior to use. The apparatus can be operated with or without metered valves. Hydrocarbon propellant cannot be filled into aerosol containers using this apparatus because large amount of propellant escapes out and vaporizes. This may lead to formation of an explosive mixture . Fluorocarbon vapors do not form any explosive or flammable mixture though their vapors are heavier than air.

PROCEDURE:

- Non aqueous products and products which can withstand low temperatures of – 40°F are used in this method.

- The product concentrate is chilled to a temperature of – 40°F and filled into already chilled container.

- Then the chilled propellant is added completely in 1 or 2 stages, depending on the amount.

- Another method is to chill both the product concentrate and propellant in a separate pressure vessel to – 40 °F and then filling them into the container.

- The valve is placed and crimped on to the container.

- Then test for leakage and strength of container is carried out by passing container into a heated water bath, where the contents of the container are heated to 130°F. After this, the containers are air dried , capped and labeled.

- Various units used in cold filling methods are : Unscrambler, Air cleaner ,Concentrate filler ,Propellant filler ,Valve placer ,Valve crimper ,Water bath ,Labeler, Coder and Packing table .

- The cold filling method is no longer being used, as it has been replaced by pressure filling method.

Advantages:

- Easy process .

Disadvantages :

- Aqueous products, emulsions and those products adversely affected by cold temperature cannot be filled by this method.

Figure 2 – Cold Filling Apparatus

COMPRESSED GAS FILLING APPARATUS – Compressed gases have high pressure hence a pressure reducing valve is required. The apparatus consists of delivery gauge. A flexible hose pipe which can withstand 150 pounds per square inch gauge pressure is attached to the delivery gauge along with the filling head. A flow indicator is also present in specialized equipments.

PROCEDURE :

- The product concentrate is filled into the container.

- Valve is placed and crimped on the container.

- With the help of vacuum pump the air is removed from the container.

- Filling head is put in the opening of the valve and the valve is depressed and the gas is allowed to flow in to container.

- The gas stops flowing if the delivery pressure and the pressure within the container become equal.

- Carbon dioxide and nitrous oxide is used if more amount of gas is required.

- High solubility of the gas in the product can be achieved by shaking the container manually or with the help of mechanical shakers.

Multiple choice questions:

1.____ methods have been used to package aerosol products.

a)1

b)2

c)3

d)4

2.Depending on the nature of the product concentrate, the aerosol can be filled by

a)cold-filling

b)pressure-filling

c)both of these

d)none of these

3.Manufacture of pharmaceutical aerosols can be done by

a)Pressure filling apparatus

b)Cold filling apparatus

c)Compressed gas filling apparatus

d)All of these

4.It consists of a pressure burette capable of metering small volumes of liquefied gas into the aerosol container under pressure. Identify

a)Pressure filling apparatus

b)Cold filling apparatus

c)Compressed gas filling apparatus

d)All of these

5.In Pressure filling apparatus the trapped air escapes out from

a)upper valve

b)lower valve

c)middle valve

d)all of these

6.In Pressure filling apparatus the propellant stops flowing when the pressure of burette and container becomes

a)equal

b)0

c)1

d)none of these

7.In Pressure filling apparatus the pressure exerted by ____ helps in the flow of the propellant into the container

a)Hydrogen

b)Argon

c)CFC

d)Nitrogen

8.Which of the following is not a disadvantage of pressure filling apparatus?

a)Certain types of metering valves can be handled only by the cold filling process or through use of an under the cap filler and valve crimper

b)Process is slower than Cold filling method

c)Loss of propellant is less

d)None of these

9..Which of the following is/are advantages of pressure filling apparatus?

a)Solutions, emulsions, suspensions can be filled by this method as chilling does not occur

b)Contamination due to moisture is less

c)High production speed can be achieved

d)All of these

10.It consist of an insulated box fitted with copper tubings and the tubings are coiled to increase the area exposed to cooling. Identify

a)Pressure filling apparatus

b)Cold filling apparatus

c)Compressed gas filling apparatus

d)All of these

11.Before use the insulated box in cold filling apparatus should be filled with

a) dry ice

b)acetone

c)ethanol

d)a and b

12.Hydrocarbon propellant cannot be filled into aerosol containers using cold filling apparatus because large amount of propellant escapes out and vaporizes. This may lead to formation of an explosive mixture.

a)true

b)false

13.Advantage of cold filling apparatus is

a)Solutions, emulsions, suspensions can be filled by this method as chilling does not occur

b)Contamination due to moisture is less

c)High production speed can be achieved

d)Easy process

14.This apparatus consists of delivery gauge. identify

a)Pressure filling apparatus

b)Cold filling apparatus

c)Compressed gas filling apparatus

d)All of these

15.Which gas can be is used if more amount of gas is required in Compressed gas filling apparatus?

a)Carbon dioxide

b)Nitrous oxide

c)Nitrogen

d)a and b

Solutions:

- b)2

- c)both of these

- d)All of these

- a)Pressure filling apparatus

- a)upper valve

- a)equal

- d)Nitrogen

- c)Loss of propellant is less

- d)All of these

- b)Cold filling apparatus

- d)a and b

- a)true

- d)Easy process

- c)Compressed gas filling apparatus

- d)a and b

References:

- Remington Essential of Pharmaceutics, 1st edition 2013, page no. 643-644.

- The Theory & Practice Of Industrial Pharmacy by Leon Lachman , H.A.Lieberman, 4th edition.

List of Successful GPATINDIAN CANDIDATES

Participate in Online FREE GPAT TEST: CLICK HERE

Participate in Online FREE Pharmacist TEST: CLICK HERE

Participate in Online FREE Drug Inspector TEST: CLICK HERE

Participate in CSIR NET JRF Mock Test