Hammer mill Principle, Construction, Uses, Advantage, Disadvantage, and Question Answer for GPAT, GATE, Pharmacist, Drug Inspector & NIPER JEE Exam

Principle

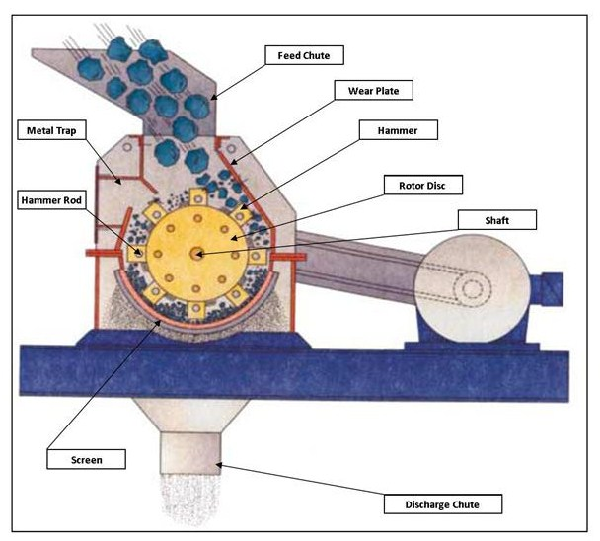

The hammer mill works on the principle of impact. Here impact occurs between the fast moving hammers which are fitted on a rotor and the feed material.

Construction

The hammer mill is of two types: either vertically shafted type or horizontally shafted type. The surface of mill where impact occurs is made of abrasive resistant material like haystellite or curably. Hammer is made up of hard steel or stainless steel. In pharmaceutical industries, mainly hammers of stainless steel are used.

Hammers are of various shapes, but the two widely used hammers are stirrup shaped or bar shaped. Bar shaped hammers are majorly used for tablet granulation. The blades attached to the hammers may be with flat edges or sharp edges or both according to the need. Hammers may be either rigid or swing type. The main advantage of using swing-type hammer is that there will be increase in clearance between the hammers and screen when excess of bulk occurs in mill.

The mill is enclosed with a chamber containing removable screen through which materials must pass. These screens are made of metal sheets and are not woven type. The thickness of metal sheet varies with perforated holes or slots.

Working

The hammers are in constant motion with a speed of 8000-15000 rotations per minute. When these hammers are in continuous motion, the feed is placed in the hopper which then flows vertically downwards due to gravity and then horizontally. Impact occurs when the rotating hammers beat the feed to get smaller particles. These size reduced particles then pass through the screen. And due to the tangential shaped exit, the size of particles is comparatively smaller.

The screens are interchangeable. This helps to achieve any grade of fineness as required. Large amount of air is drawn through the mill since the hammers work as centrifugal fans. In some cases, the air drawn is sufficient to counter act the heat generated during the process. The size of particle depend on the following-

- Feed rate

- Rotor velocity

- Clearance between hammers and screen

- No and type of hammer used

- Size of screen

Uses

- On depending on the speed of hammer, fine to moderate grinding can be done through this mill.

- The expected particle size varies from 10-400 micro-meters.

- Non-abrasive to moderately abrasive, brittle materials can be size reduced

- Ointments, slurries, wet-filter press cakes can be milled.

Advantages

- Hammer mill is easy to install and clean

- Different types of feed material can be size reduced using different size of screens

- It occupies less space

- It is a versatile mill

- Since it is operated in close container so possibility of degradation is less.

Disadvantages

- The screen may get clogged

- Excessive heat is generated, therefore product may get degraded

- It cannot be used for sticky, fibrous and hard materials

Variants

- Fitzpatrick comminuting machine (Fitz mill):- used for drugs, roots, herbs, glands, liver and soaps.

- Stokes tornado mill

- Micro-pulveriser:- it is used for sugars, chemicals and cosmetics.

Multiple Choice Questions (MCQs)

1. Hammer mill works on the principle which mode of stress?

A. Impact

B. Attrition

C. Compression

D. Both A and B

2. The mode of stress is applied between which two components in Hammer Mill?

A. Hammer and rotor

B. Hammer and feed

C. Rotor and Feed

D. None of the above

3. Hammers are made of which type of material in Hammer Mill?

A. Haystellite

B. Curably

C. zinc

D. None of the above

4. Which shaped hammers are used for tablet granulation?

A. Bar

B. Stirrup

C. Bell

D. None of the above

5. Match the following-

A. Milling surface is made of 1. No. of rotations per minute

B. Hammers are made of 2. Feed rate

C. particle size depends on 3. Stainless steel

D. Flow of particles depends on 4. Curably

6. Which of the following factor affect the particle size of feed material?

A. Rotor speed

B. No. of hammer

C. Size of screen

D. All of the above

7. What is the benefit of interchangeable screens in hammer mill?

A. Speed of hammer can be changed

B. Any grade of fine particle can be achieved

C. Both

D. None

8. Which type of material is size reduced by hammer mill?

A. Fibrous

B. Soft

C. Brittle

D. All of the above

9. Which of the following statement is NOT true in Hammer Mill?

A. Only one type of hammer is used in hammer mill

B. Size reduction depends on rotor velocity

C. Fitz mill is used for roots and soaps

D. None

10. Why is hammer mill called as a versatile mill?

A. Screens can be changed rapidly

B. Speed can be changed easily

C. Both

D. None

ANSWERS:-

- Impact

- Rotor and feed

- None of the above

- Bar

- A – 4 B – 3 C – 2 D – 1

- All of the above

- Both

- Brittle

- Only one type of hammer is used in hammer mill

- BothFor More Standard and Quality Question Bank you can Join Our Test Series Programme for GPAT, NIPER JEE, Pharmacist Recruitment Exam, Drug Inspector Recruitment Exams, PhD Entrance Exam for Pharmacy

List of Successful GPATINDIAN CANDIDATES

Participate in Online FREE GPAT TEST: CLICK HERE

Participate in Online FREE Pharmacist TEST: CLICK HERE

Participate in Online FREE Drug Inspector TEST: CLICK HERE

Participate in CSIR NET JRF Mock Test